Have you ever wondered how a block of metal turns into a car engine part or how a wooden slab becomes a beautifully carved piece of furniture? Behind these transformations lies a fascinating blend of computer programming, physics, and engineering called computer-controlled cutting and shaping. This is not just about machines following instructions but about how human creativity meets scientific precision. It’s the science that powers modern manufacturing, blending art with accuracy in ways that seem almost magical.

What Is Computer-Controlled Cutting?

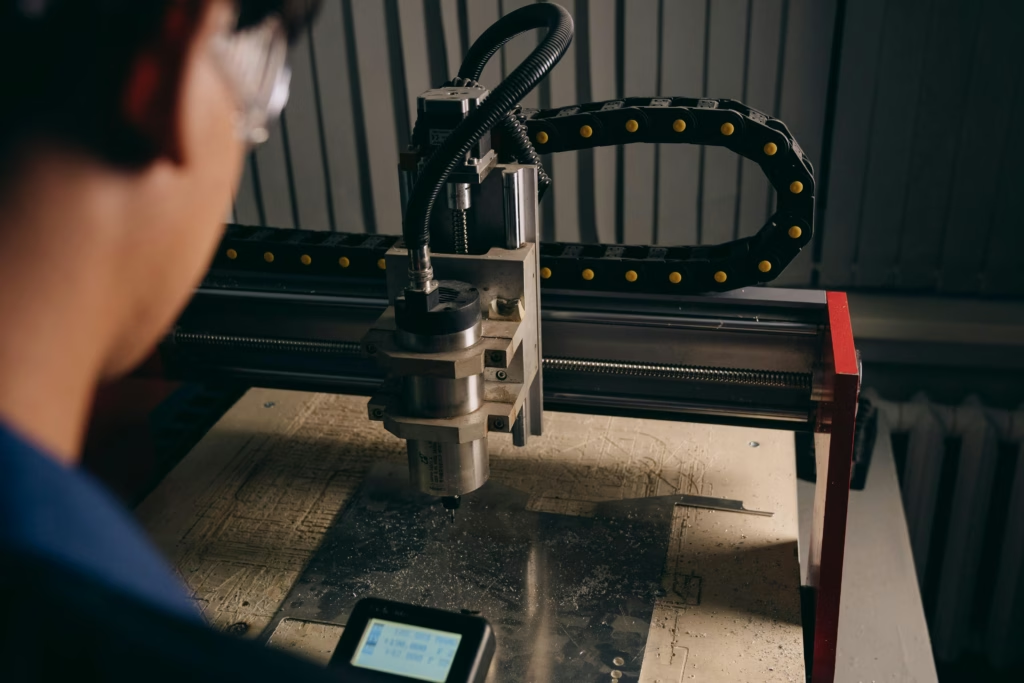

Computer-controlled cutting is the process where computers guide cutting tools or machines to remove material from a workpiece in a highly accurate way. These machines are often called CNC (Computer Numerical Control) machines. The computer reads a digital design—usually a CAD (Computer-Aided Design) file—and translates it into specific tool movements that carve, cut, drill, or shape materials into exact forms.

It’s like having a robotic craftsman that never gets tired, never makes a mistake, and follows every command with microscopic precision. But how does it actually work? To understand that, we need to look at the science that drives it.

How CNC Machines Think

At the heart of every CNC machine is a computer processor that converts digital blueprints into numerical commands. These commands are often written in a programming language called G-code. This code controls every movement of the tool, from how fast it spins to how deep it cuts.

Each line of code represents a coordinate in three-dimensional space, allowing the machine to position its tool head with extreme accuracy—sometimes within a few microns. This level of precision is achieved through the combination of mathematics, control systems, and feedback mechanisms.

Sensors constantly monitor position, speed, and torque. If the tool starts to drift or encounter resistance, the system instantly adjusts, ensuring consistent performance. It’s a seamless dance between software and hardware, choreographed by physics and computing.

The Materials Science Behind Perfect Cuts

Cutting and shaping materials isn’t just about movement. It’s about understanding how different materials behave under pressure, heat, and friction. This is where materials science comes in.

When a CNC machine cuts into metal, the cutting edge generates heat. Too much heat can damage both the tool and the material. Engineers must calculate the perfect feed rate, spindle speed, and cutting depth based on the material’s hardness, thermal conductivity, and tensile strength.

For instance, aluminum conducts heat well and can be cut at high speeds, while titanium is much tougher and requires slower, more controlled cutting to prevent tool wear. The interplay of temperature, force, and motion is a finely tuned scientific process that ensures each cut is clean and precise.

The Physics of Motion and Control

Every movement in a CNC machine is governed by the laws of physics. Newton’s laws of motion, frictional forces, and vibrations all play a crucial role in how accurately a machine can perform.

Linear motion is achieved using motors that drive lead screws or ball screws, converting rotational energy into smooth, precise linear motion. These screws are engineered to minimize backlash—a small error caused by mechanical play between moving parts.

Rotational motion is controlled through servo or stepper motors, which receive electrical pulses from the computer. Each pulse corresponds to a small movement, allowing for exact positioning. The feedback loop between the motors and the computer ensures every motion aligns perfectly with the programmed path.

This intricate system of motion control, energy conversion, and feedback is what allows CNC machines to operate at such astonishing levels of precision and repeatability.

The Role of Computer Algorithms in Shaping

Cutting and shaping aren’t random actions—they’re guided by algorithms designed to optimize paths, minimize waste, and reduce machining time. Advanced software analyzes the geometry of a design and determines the most efficient tool path to achieve the desired shape.

These algorithms take into account the material properties, tool geometry, and even the potential for vibration or thermal expansion during cutting. Modern systems use artificial intelligence and machine learning to adapt these paths in real-time, predicting tool wear and adjusting cutting parameters automatically.

The result is a process that’s not only efficient but also self-improving. The more data the system processes, the smarter it becomes at predicting outcomes and reducing errors.

The Importance of Calibration and Feedback

Even the most advanced machine needs feedback to maintain accuracy. Sensors play a crucial role in this process. They monitor temperature, position, vibration, and torque, constantly sending data back to the control system.

For example, laser interferometers can measure position changes at the nanometer level, ensuring the cutting head moves exactly where it should. If an error occurs due to thermal expansion or tool deflection, the machine can automatically compensate, recalibrating itself in real time.

This dynamic feedback loop transforms CNC machining into a living system—constantly sensing, learning, and correcting to maintain flawless results.

The Evolution of Computer-Controlled Cutting

The journey from manual machining to computer-controlled systems is a story of innovation and human ingenuity. Early machines relied on mechanical templates and operator skill. The introduction of numerical control in the mid-20th century replaced manual levers with programmed instructions, allowing machines to follow precise digital commands.

With the arrival of microprocessors, CNC technology became even more sophisticated. Today’s machines integrate sensors, AI-driven optimization, and cloud connectivity, allowing manufacturers to monitor performance from anywhere in the world.

This evolution represents more than just technological advancement—it’s a shift in how we think about making things. Machines have become extensions of human creativity, capable of turning imagination into physical reality with atomic-level accuracy.

The Science of Cutting Tools

While the computer and control system get most of the attention, the real magic happens at the cutting edge. Cutting tools are carefully designed using advanced metallurgy and geometry to achieve specific results.

Each tool is shaped to create an ideal cutting angle, reducing friction and directing heat away from the cutting zone. The materials used—often carbide, ceramic, or diamond-coated—are chosen for their hardness, wear resistance, and thermal stability.

Engineers use finite element analysis (FEA) to simulate how these tools will perform under different loads, temperatures, and speeds. This predictive modeling allows for the creation of tools that last longer and perform better, pushing the boundaries of what machines can achieve.

The Chemistry of Coolants and Lubrication

Cutting generates intense heat, and controlling that heat is vital to maintaining precision. That’s where coolants and lubricants come in. Their chemistry is carefully engineered to reduce friction, remove chips, and carry heat away from the cutting zone.

Different cutting fluids are designed for specific materials and operations. Water-based coolants are ideal for high-speed machining, while oil-based lubricants work better for heavy-duty applications. Some modern systems even use dry or minimum-quantity lubrication to reduce waste and environmental impact.

This intersection of chemistry and engineering ensures both the tool and the workpiece remain within safe temperature ranges, preserving accuracy and tool life.

Digital Design Meets Physical Reality

The bridge between digital and physical worlds is where the true science of computer-controlled cutting shines. Engineers start with a 3D digital model, often designed in CAD software. This model is then translated into CAM (Computer-Aided Manufacturing) data that defines tool paths, speeds, and feeds.

The transition from virtual design to physical product must account for real-world factors like material stress, tool deflection, and thermal distortion. Engineers use simulation software to predict these effects and adjust the process before cutting even begins.

This digital twin approach—creating a virtual replica of the manufacturing process—allows for testing, optimization, and validation long before a single piece of material is touched.

The Role of Artificial Intelligence in Modern Machining

Artificial intelligence is changing the landscape of computer-controlled manufacturing. AI systems analyze massive amounts of data from sensors, learning patterns and optimizing performance over time. They can predict when a tool is about to fail, adjust feed rates to prevent errors, or even suggest better cutting strategies.

Machine learning algorithms process vibration data, sound frequencies, and temperature changes to detect anomalies before they cause defects. This predictive maintenance not only improves quality but also saves time and cost, ensuring machines run efficiently with minimal downtime.

In the near future, we may see fully autonomous machining systems capable of self-diagnosis, self-repair, and adaptive optimization, blending science fiction with industrial reality.

The Human Element in Computer-Controlled Science

Despite all the automation, human expertise remains at the core of this technology. Engineers, programmers, and machinists bring creativity, intuition, and experience to the process. They understand the nuances of materials, the feel of a perfect cut, and the artistry behind every design.

Computer-controlled cutting doesn’t replace human craftsmanship—it enhances it. It gives creators the ability to push boundaries, experiment with complex geometries, and achieve levels of detail that were once impossible.

The partnership between human intelligence and machine precision is what truly defines this field. It’s a collaboration where science empowers imagination.

The Future of Computer-Controlled Cutting

The future of computer-controlled cutting lies in integration and intelligence. Machines will communicate seamlessly with one another, using real-time data to coordinate entire production lines. Quantum computing and nanotechnology could bring levels of precision that approach molecular control.

We might see hybrid machines that combine cutting, additive manufacturing, and surface treatment in a single process, creating fully finished products in one operation. Sustainability will also play a major role, with energy-efficient systems and recyclable materials becoming standard practice.

Ultimately, the science behind computer-controlled cutting is evolving toward a new era—one where design, data, and automation merge into a continuous cycle of innovation.

Conclusion

Computer-controlled cutting and shaping is a brilliant fusion of science, technology, and creativity. It draws from physics, chemistry, mathematics, and engineering to transform digital dreams into tangible masterpieces. Every precise movement, every smooth surface, and every flawless edge is a testament to human curiosity and scientific mastery.

Whether it’s crafting aerospace components, medical implants, or artistic sculptures, this technology proves that science is not just about understanding the world—it’s about shaping it.

Computer-controlled cutting stands as one of humanity’s most powerful tools for creation, precision, and progress, turning the invisible logic of code into the visible beauty of craftsmanship.