Imagine this. You create a sleek, detailed design on your computer—a logo, a nameplate, or an intricate pattern. Then, within hours, that same digital design appears engraved onto a piece of metal, wood, or glass, perfectly etched down to the finest line. It almost feels magical, but the process behind it is a beautiful blend of science, artistry, and technology.

Engraving has evolved from being a slow, manual craft into a precise digital art form. What once required steady hands and years of experience can now be achieved with the help of computer-controlled machines, though the human touch is still essential. Today, engravers don’t just carve surfaces—they bring digital ideas to life in ways that are both visually stunning and technically flawless.

The Evolution of Engraving: From Hand Tools to High-Tech Precision

The story of engraving begins centuries ago. Ancient artisans used sharp tools made of bronze or iron to carve patterns, inscriptions, and images into stone, metal, and wood. Every stroke was guided by hand, often taking days to complete a single piece. The process was laborious, but the results were treasured artworks and records of history.

As time passed, engraving became central to industries like printing and jewelry-making. The invention of steel engraving tools allowed for more detailed work, especially on metals like copper or silver. Yet even then, engravers relied entirely on manual skill.

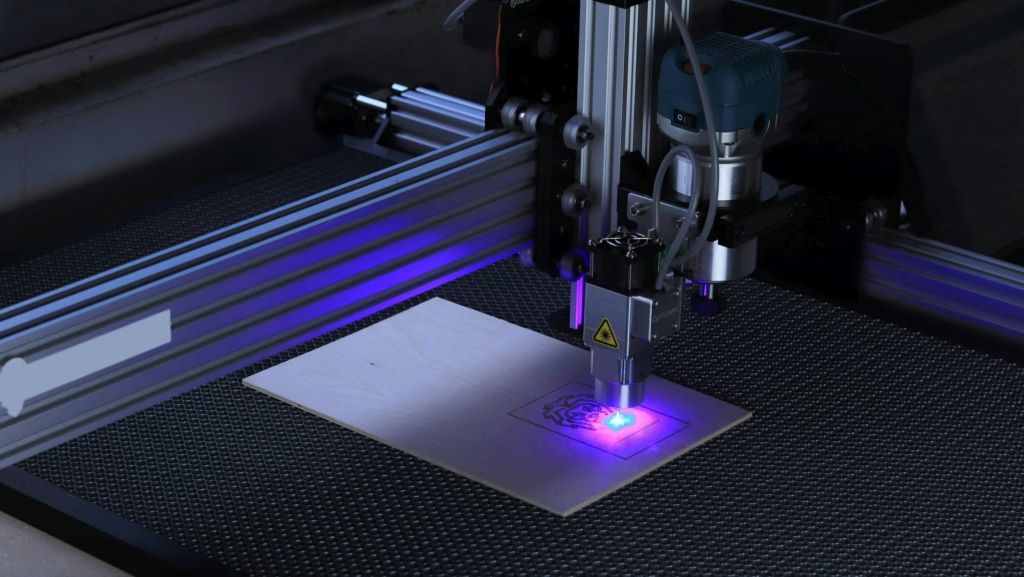

The real revolution came with the rise of computer-controlled engraving machines. Suddenly, what used to take weeks could be done in hours. Today’s engravers use digital files, specialized software, and laser or rotary engraving machines to achieve levels of precision that were once impossible by hand.

While machines have taken over the heavy lifting, the engraver’s role remains vital. Understanding how to translate a digital image into a physical engraving still requires knowledge of materials, tool settings, and artistic intuition.

The Digital Beginning: Designing with Precision

Every modern engraving project starts with a digital design. This design can be created in vector-based software like Adobe Illustrator, CorelDRAW, or CAD programs used for technical drawings. The key here is precision. Unlike images made up of pixels, vector designs rely on mathematical paths that define shapes and lines. This ensures the design can be scaled infinitely without losing detail or clarity.

Once the design is ready, the engraver prepares it for engraving by adjusting parameters like line thickness, depth, and contrast. These adjustments depend on the type of engraving machine and material being used. A design that looks perfect on screen might not engrave well if the lines are too thin or too close together.

This is where artistic judgment meets technical understanding. The engraver must visualize how the digital file will appear once etched into a surface. They know how light interacts with engraved lines and how certain materials respond to different depths of engraving.

Machines that Make It Happen

When it comes to transforming digital designs into engraved masterpieces, two main technologies dominate the scene: laser engraving and rotary engraving. Each has its unique strengths and ideal applications.

Laser Engraving

Laser engraving uses a focused beam of light to vaporize or discolor the surface material. It’s incredibly precise, capable of reproducing intricate patterns, text, and even photographs. Because lasers don’t physically touch the surface, there’s no tool wear or mechanical stress, making it perfect for delicate materials like glass, leather, or acrylic.

Laser engravers are widely used for personalized gifts, awards, signage, and branding items. They can work with a wide range of materials, and their software interfaces directly with design files, ensuring the engraved result matches the original design with microscopic accuracy.

Rotary Engraving

Rotary engraving uses a spinning cutting tool, or burin, to physically carve into the surface. It removes material to create a deep, tactile effect that you can feel with your fingers. This traditional method is ideal for metals, woods, and plastics.

While rotary engraving may seem old-fashioned next to lasers, it offers a distinct look and feel that many clients prefer. The depth and texture give engraved pieces a sense of permanence and craftsmanship.

Preparing the Design for Engraving

Before engraving begins, the digital file must be translated into a format the machine understands. This involves converting the design into tool paths or laser instructions. Software like Gravostyle, LightBurn, or RDWorks helps engravers control how the machine moves, what speed it operates at, and how deep or intense the engraving should be.

The engraver sets parameters such as power level, speed, frequency, and focus for laser systems or tool type, spindle speed, and feed rate for rotary systems. Each combination affects the final result. Too much power might burn or warp the surface, while too little might make the design faint or incomplete.

This preparation stage is critical because it determines the quality and accuracy of the final engraving. Skilled engravers often perform test runs on scrap material before committing to the final piece, ensuring every line and curve appears as intended.

The Engraving Process in Action

Once the setup is complete, the machine begins its work. For laser engraving, the beam rapidly moves across the surface, following the digital pattern. It removes or alters the top layer of material to create the design. The process is surprisingly quiet and clean, producing intricate results in minutes.

In rotary engraving, the cutting tool glides and spins across the material, removing small amounts of it with each pass. The engraver monitors the process closely, especially for multi-pass engravings that require deeper cuts. While slower than lasers, rotary engraving produces a more tactile finish, ideal for applications like nameplates, jewelry, or industrial labels.

The level of precision these machines achieve is extraordinary. Tiny fonts, detailed graphics, and complex textures appear effortlessly, faithfully replicating the original digital design.

Choosing the Right Material

Different materials react differently to engraving, so choosing the right one is key to achieving the desired effect.

Metal

Metals like stainless steel, brass, and aluminum are popular for their durability and shine. Laser engraving darkens the surface, while rotary tools carve deeper marks. Metals are ideal for plaques, machinery labels, and luxury branding.

Wood

Wood engraves beautifully, producing warm, natural contrasts. Lasers bring out rich tones by burning the surface, while rotary engraving creates deeper grooves that highlight the grain. Perfect for signs, décor, and personalized gifts.

Glass and Acrylic

Glass engraving produces frosted, elegant designs that catch light beautifully. Acrylic offers a similar effect but allows for more control and color options. Laser engravers excel at these materials, producing crystal-clear results.

Plastics and Leather

Plastics can be laser-engraved for signage or industrial tags, while leather engraving adds sophistication to wallets, belts, and bags. Each material requires careful adjustment of machine settings to avoid burning or melting.

The Role of the Engraver’s Skill

Despite the automation and digital precision, engraving remains an art. Machines may follow instructions, but the engraver decides how those instructions translate into visual beauty. Knowing which parameters to tweak, how deep to cut, and which material to choose are all part of the craft.

A skilled engraver understands how to make a flat digital image feel alive once it’s engraved. They can manipulate textures, play with contrast, and enhance depth to make designs pop. When you hold a finished engraved piece, you’re not just seeing a design—you’re feeling the engraver’s mastery at work.

Adding the Finishing Touches

Once engraving is complete, the work isn’t over. Many pieces require finishing touches to enhance appearance and durability.

For metals, this might include polishing or filling engraved areas with colored enamel. Wood engravings might be sanded or varnished to protect the surface. Glass and acrylic pieces are cleaned and sometimes illuminated with LED backlighting for dramatic effect.

These final steps turn a precise engraving into a polished masterpiece ready for display or use.

Applications of Modern Engraving

Engraving is everywhere, often in places we don’t even notice. From the branding on your laptop to the serial number on your phone, engraving ensures information lasts. It’s also found in luxury products, personalized gifts, architectural signage, and even art installations.

Jewelry engraving remains one of the most emotional applications. A name, date, or short message permanently etched into a ring or pendant transforms it from an accessory into a cherished memory.

In industrial contexts, engraving provides permanent labeling that resists heat, wear, and chemicals—vital for safety and traceability.

Artists, on the other hand, use engraving as a creative medium, blending traditional craftsmanship with digital experimentation. Laser etching allows them to push boundaries and explore textures that would be impossible by hand.

The Human Touch Behind the Machine

Even in this age of automation, the engraver’s intuition and artistry remain central. Machines can replicate patterns, but they can’t replicate taste, style, or emotion. Every engraved masterpiece reflects the choices of the person guiding the process.

Engraving is as much about understanding materials as it is about design. The engraver reads the grain of the wood, senses the hardness of the metal, and listens to the hum of the machine, making subtle adjustments to achieve perfection.

This blend of human creativity and digital precision is what makes modern engraving so special. It bridges the gap between technology and artistry, between imagination and reality.

The Future of Engraving

The engraving industry continues to evolve with advancements in technology. High-speed fiber lasers, 3D engraving, and AI-assisted design tools are expanding what’s possible. Imagine engraving on curved surfaces, creating layered textures, or even embedding augmented reality markers within designs.

Sustainability is also becoming a priority. New machines are energy-efficient, and materials are being chosen for their environmental friendliness. Digital design workflows reduce waste, allowing engravers to test virtually before touching any physical material.

As technology progresses, the line between art and engineering grows thinner, opening endless possibilities for creators.

Where Digital Dreams Become Tangible

The journey from a digital file to a finished engraving is a fascinating dance between creativity and precision. Every engraved masterpiece begins as an idea—a vision captured in pixels—that transforms into something you can touch, see, and treasure.

Engravers are the unseen artists who give digital designs physical form. They harness technology not to replace artistry, but to enhance it. Each line cut, each beam of light, and each polished surface tells a story of patience, precision, and passion.

When you look at a beautifully engraved object—a name on a trophy, a logo on a metal plate, or a pattern on glass—you’re witnessing the meeting of art and innovation. It’s where digital dreams become tangible, where craftsmanship meets creativity, and where ordinary materials are transformed into lasting masterpieces.