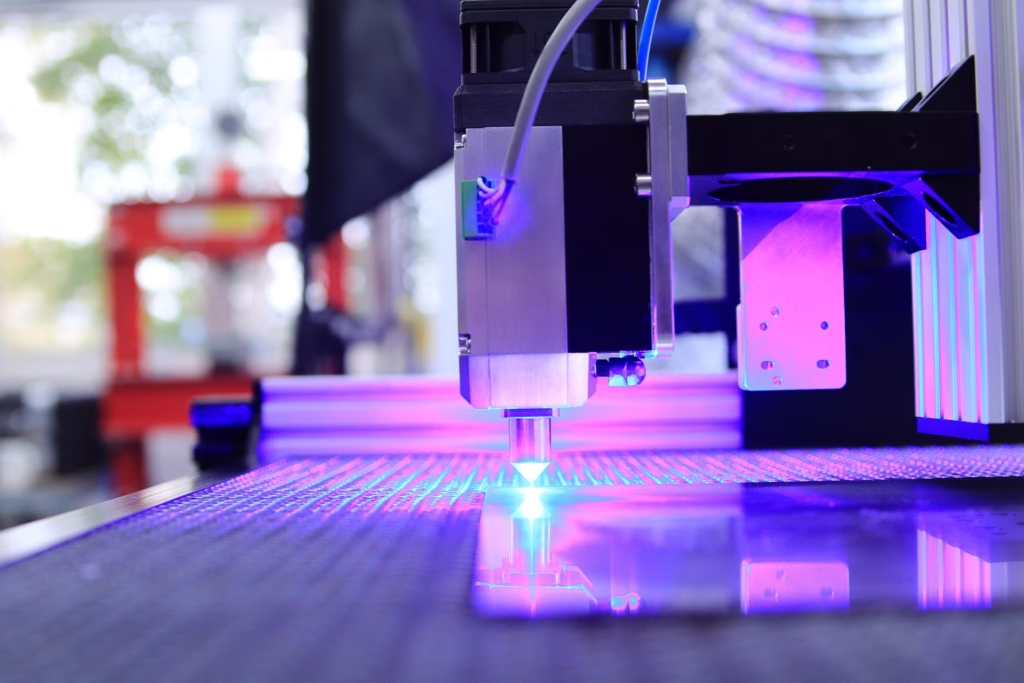

Picture a beam of light so focused it can slice through steel like a knife through butter. No friction, no physical contact—just pure energy guiding its way with millimeter-level accuracy. That’s the world of laser cutting, a technology that has transformed how we shape materials in industries from aerospace to art.

Laser-based cutting is one of those marvels of modern engineering that seems almost otherworldly. Instead of using blades, plasma, or physical tools, it relies on highly concentrated light energy to cut, engrave, or mark a surface. It’s fast, clean, and incredibly precise, capable of producing details finer than a human hair.

What Is Laser Cutting?

Laser cutting is a manufacturing process that uses a focused beam of light to cut through materials. The word “laser” stands for Light Amplification by Stimulated Emission of Radiation—a mouthful that simply means light energy amplified to extreme intensity.

A laser cutter works by directing this intense beam through lenses or mirrors to a single point on the surface of a material. The energy heats the material rapidly until it melts, vaporizes, or burns away. Since the beam is so narrow and precise, the cuts are incredibly clean and detailed.

What makes it even more powerful is that the entire process is guided by computers. Laser cutters are often integrated with CNC (Computer Numerical Control) systems that control the motion of the laser with digital precision. This means you can upload a digital design, press start, and watch as the machine follows your pattern perfectly.

The Science Behind the Beam

At first glance, it seems almost magical that light alone can cut through metal. But the science is beautifully logical. A laser beam is made up of photons—tiny packets of energy. When a laser generator concentrates these photons into a coherent beam, they move in perfect alignment, amplifying their power.

This concentrated beam has an extremely high energy density. When it strikes a surface, the energy is absorbed and converted into heat. The intense heat either melts or vaporizes the material in its path.

Different types of lasers achieve this in various ways, using gases, crystals, or semiconductors to generate and control the beam. What’s common across all of them is the ability to focus energy with astonishing precision.

Types of Laser Cutters

Not all laser cutters are created equal. There are several types, each designed for specific materials and levels of precision.

CO₂ lasers are among the most common and versatile. They use a mixture of carbon dioxide, nitrogen, and helium gases to produce an infrared beam. CO₂ lasers are ideal for cutting non-metallic materials like wood, acrylic, plastic, and even leather, though they can also cut thin metals.

Fiber lasers are a newer technology that uses optical fibers doped with rare-earth elements like ytterbium to amplify the light. These lasers are exceptionally efficient and powerful, making them ideal for cutting metals such as steel, aluminum, brass, and copper. They’re also known for their low maintenance and high cutting speeds.

Crystal lasers, such as Nd:YAG and Nd:YVO₄, use solid crystal rods to generate the laser beam. They can deliver high energy in short bursts, which makes them excellent for detailed engraving and very fine cuts on metals and ceramics.

Each type has its strengths, and the choice depends on what material you’re cutting and how precise you need to be.

How CNC Control Elevates Laser Cutting

While the laser provides the cutting power, CNC control gives it direction and intelligence. Think of CNC as the brain behind the laser’s brilliance.

The process begins with a design created in CAD (Computer-Aided Design) software. That design is then translated into G-code, the programming language that instructs the CNC system. The machine interprets this code to guide the laser along precise paths, adjusting speed, focus, and intensity as it goes.

This automation ensures every movement is controlled down to fractions of a millimeter. Whether it’s cutting intricate gears for machinery or delicate patterns in jewelry, the CNC system ensures absolute consistency from start to finish.

CNC control also allows for repeatability—once a design is perfected, it can be reproduced flawlessly as many times as needed. That’s why laser CNC machines are a favorite in industries that demand uniformity and accuracy, like aerospace engineering, automotive manufacturing, and electronics.

The Role of Optics: Focusing Light into Power

The heart of every laser cutter is its optical system. Mirrors or lenses guide and focus the laser beam onto the workpiece. The smaller and sharper the focus, the finer the cut.

Modern laser systems use adjustable lenses that can change the focal length to suit different materials and thicknesses. The focus must be just right—too close and the beam might scatter; too far and it loses its power.

Automatic height control systems keep the laser’s focus consistent, even if the material’s surface isn’t perfectly flat. This ensures every part of the cut stays sharp and smooth.

It’s fascinating how much of this process depends on light behaving like a tool. Instead of a blade slicing through material, it’s a perfectly controlled ray of photons doing the work—fast, clean, and silent.

Materials That Laser Cutting Can Handle

One of the biggest advantages of laser cutting is its versatility. It can handle a wide range of materials with remarkable precision.

Metals: Fiber and crystal lasers easily cut steel, aluminum, copper, and brass. The precision is so fine that even thin-walled or intricate metal parts can be produced without distortion.

Plastics and Acrylics: CO₂ lasers are excellent for cutting or engraving plastic materials. Acrylic, in particular, cuts cleanly and leaves polished edges that look like they were finished by hand.

Wood and Paper: Laser cutters are commonly used in woodworking and packaging industries for making decorative patterns, signs, and prototypes. They can cut fine details without splintering or burning.

Textiles and Leather: Fashion designers use laser cutting to create intricate patterns that would be impossible with scissors or blades. The heat seals fabric edges as it cuts, preventing fraying.

Glass and Ceramics: With proper settings, lasers can etch or engrave glass surfaces without cracking them, creating detailed designs for art or industrial purposes.

The ability to work across so many materials makes laser cutting an indispensable tool in both manufacturing and creative industries.

The Unmatched Precision of Lasers

Precision is where laser cutting truly shines. The focused beam can be as small as a few microns wide, allowing for extremely fine detailing. That’s why it’s often used for components that require tight tolerances, such as medical instruments, electronic circuits, and aerospace parts.

Since there’s no physical contact between the laser and the material, there’s minimal mechanical stress. That means no warping, chipping, or tool wear—issues that often occur with traditional cutting methods. The result is a perfectly smooth edge that needs little or no finishing.

This level of precision also allows designers to experiment more freely. Complex patterns, curves, and geometries that were once difficult to achieve can now be created effortlessly. It’s precision that empowers creativity.

The Speed and Efficiency of Light

Beyond precision, laser cutting is also incredibly fast. The laser beam moves at high speeds, following the programmed path without hesitation or deviation. Since the laser melts or vaporizes material instantly, there’s no need for multiple passes or manual finishing.

In mass production settings, this speed translates to higher output and lower costs. A single laser cutting machine can often replace several traditional tools, reducing setup time and simplifying workflows.

Another advantage is that laser cutters can switch quickly between different designs. Operators can load new digital files instantly without changing physical tools. This flexibility makes laser systems ideal for both prototyping and large-scale production.

Cleaner Cuts and Minimal Waste

Laser cutting isn’t just precise—it’s also efficient. Because the laser beam is so narrow, it removes only a tiny amount of material during each cut. That means less waste compared to mechanical cutting methods.

The heat-affected zone, or the area surrounding the cut, is also very small. This reduces the risk of warping or discoloration. Materials retain their structural integrity and appearance even after intense cutting sessions.

Many modern laser systems include gas assist features that blow away molten material with oxygen or nitrogen. This keeps the edges clean and prevents oxidation, further improving the finish quality.

For industries focused on sustainability and cost-efficiency, this level of resource optimization is a major advantage.

Safety and Environmental Aspects

Working with powerful laser beams requires strict safety measures. Modern laser cutters are enclosed in protective housings that prevent accidental exposure to the beam. Operators wear safety glasses designed to block specific wavelengths of light.

Ventilation systems capture and filter out fumes or particles produced during cutting, keeping the workspace clean and safe. Many facilities also use air extraction units that recycle or neutralize exhaust gases, minimizing environmental impact.

From an energy standpoint, laser cutting is surprisingly efficient. Fiber lasers, in particular, convert electrical energy into light with minimal loss, making them more eco-friendly than many traditional cutting systems.

These safety and sustainability advancements show how laser technology continues to evolve—not just for performance, but also for responsibility.

Challenges and How Technology Overcomes Them

Even a technology as advanced as laser cutting comes with challenges. Reflective metals like copper and aluminum can bounce back laser energy, making them harder to cut. Early laser systems struggled with this, but modern fiber lasers have largely solved the problem by using wavelengths that absorb better in these materials.

Another challenge is managing heat buildup. If the laser stays on one spot too long, it can cause burns or distortions. To prevent this, CNC software optimizes the cutting path, distributing heat evenly across the surface.

Maintenance and calibration are also essential. Lenses and mirrors must stay clean, and alignment must be precise to maintain beam quality. Fortunately, today’s machines come with automatic calibration and diagnostic systems that make upkeep easy.

With each new generation, laser cutting becomes more efficient, user-friendly, and adaptable.

Real-World Applications of Laser Cutting

Laser cutting touches almost every part of modern life. In automotive manufacturing, lasers are used to cut panels, exhaust components, and precision gears. In aerospace, they shape lightweight but strong parts that must withstand extreme temperatures and pressures.

Electronics manufacturers rely on laser cutting to create tiny circuit components and intricate enclosures. Medical device makers use it for surgical tools and implants where precision can mean the difference between success and failure.

Outside of industry, artists and designers use laser cutters to create stunning works of art, architectural models, jewelry, and even custom furniture. The ability to go from a digital sketch to a finished piece within minutes has opened creative possibilities like never before.

It’s a technology that connects science and creativity, enabling both engineers and artists to push the limits of what’s possible.

The Future of Laser Cutting

As powerful as laser cutting already is, the future promises even more innovation. Artificial intelligence and machine learning are starting to play a role, allowing laser systems to analyze cutting conditions in real time and adjust automatically for optimal results.

Hybrid systems are emerging that combine laser cutting with additive manufacturing or 3D printing, enabling both cutting and shaping in one continuous process.

We can also expect advances in ultrashort pulse lasers, which emit incredibly brief bursts of light to cut even the most delicate materials without causing heat damage. This will open new frontiers in fields like microelectronics and biomedical engineering.

As technology continues to evolve, laser cutting will only become faster, cleaner, and smarter—an even more essential tool for the industries of tomorrow.

Why Laser Cutting Has Changed Manufacturing Forever

Laser cutting represents the perfect union of science, precision, and creativity. It has replaced heavy tools and noisy workshops with quiet beams of light guided by digital intelligence. It’s the reason we can produce smartphones, aircraft parts, and intricate jewelry with equal perfection.

It’s not just about cutting—it’s about redefining how we think of making. Laser cutting eliminates limits, inviting designers and engineers to imagine without constraint. The accuracy is no longer a challenge but a given, allowing the focus to shift toward innovation and artistry.

Whether in a high-tech lab, a factory floor, or a small design studio, the laser cutter has become a symbol of precision craftsmanship powered by light.

Final Thoughts

Laser cutting is more than just a manufacturing process—it’s a triumph of human ingenuity. By harnessing one of nature’s most fundamental forces, light itself, we’ve created a tool capable of shaping the modern world with microscopic precision and massive impact.

From intricate jewelry to aircraft components, from art installations to medical devices, the silent brilliance of laser cutting touches everything around us. It’s a reminder that when we master light, we don’t just cut materials—we sculpt possibility.

In every glowing beam and every flawless edge, there’s a story of innovation, precision, and imagination brought to life through the science of light.